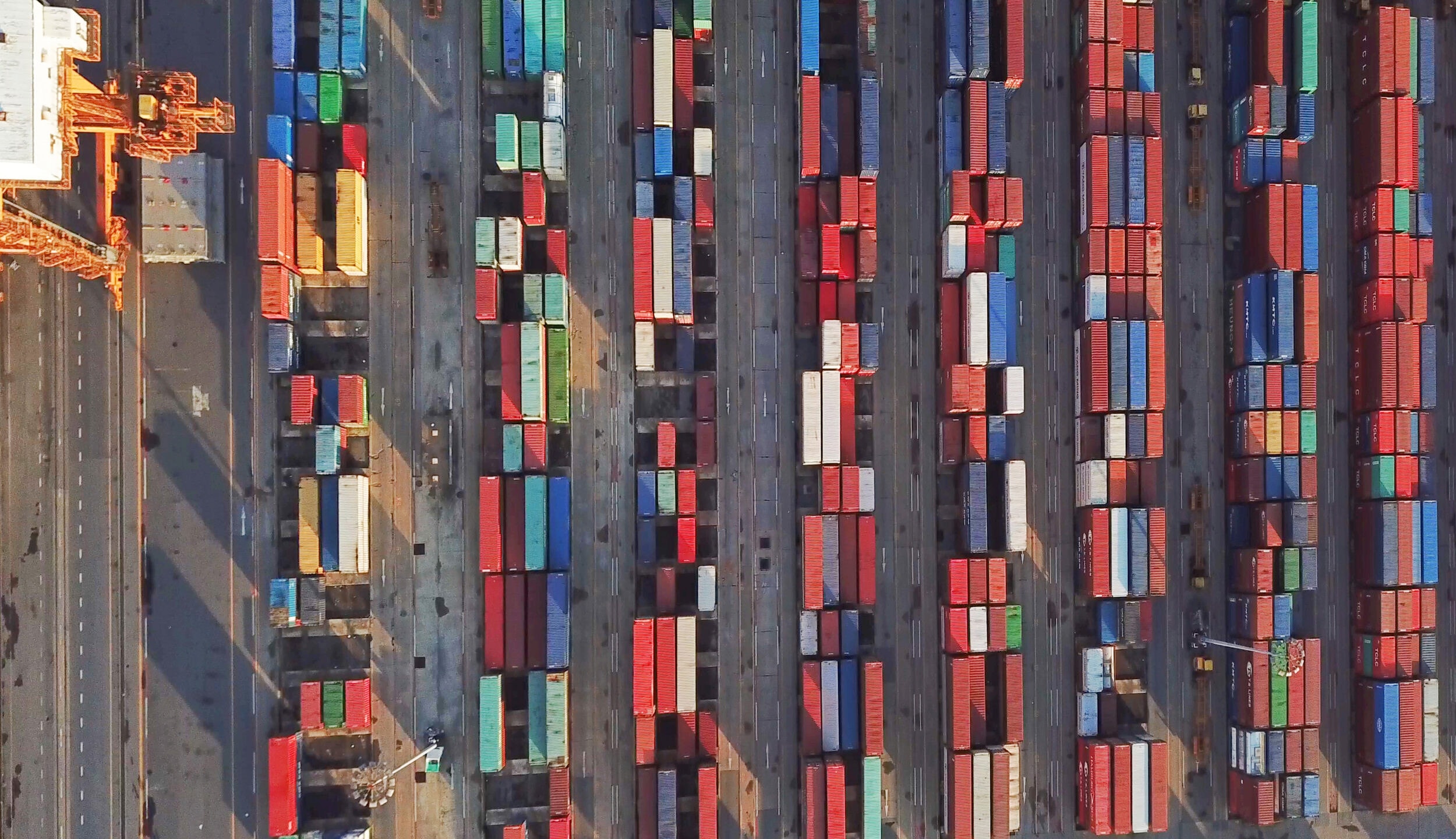

Global traders perform one of the business world’s most difficult balancing acts; finding the safe spot between having enough stock at the right time and not bleeding resources by filling warehouse upon warehouse with unsold products. This critical balancing act is rife with knotty decisions and weighty logistical calculations.

And that was before the pandemic…

Now that global supply chains and shipping times are profoundly disrupted, the performance is becoming ever more perilous.

With the global economies becoming more integrated in recent years, the volatility of trade regulations, the introduction and renegotiation of free trade agreements, and layering onto those environmental factors,Traders across the globe are being forced to adapt and improvise in a post-pandemic market.

Many are rethinking their supply chain optimization strategies to strike a balance between efficiency and liability.

Which supply chain optimization problems are global traders facing? Is just-in-time restocking a thing of the past? Is there such a thing as over-optimization? What tools can help traders with supply chain optimization? Let’s dive in.

Supply Chain Optimization in a Post-Pandemic Trade Market

The global supply chain is currently a chaotic subject. A global pandemic, shortages, trade wars, literal wars, economic downturns, shipping delays, and unpredictable demand have severely complicated the global supply chain.

While it may appear overly simplified, globalized companies everywhere are experiencing these two basic problems:

- Too much inventory

OR

- Too little inventory

Some manufacturers and retailers face the logistical nightmare of facing both issues simultaneously with different products. In view of these profit-losing problems, which inventory strategies are companies starting to re-think?

Just-in-Time (JIT) Inventory – Is it Outdated?

Prior to the pandemic, many traders had their supply chain strategy dialed in, using the just-in-time restocking method. Companies wanted just enough stock on hand to replenish shelves as they emptied but not enough to necessitate extensive warehouse storage.

“Up until 2020, the world’s largest corporations relied on a best-in-class standard for process and supply chain management known as “just-in-time” inventory (JIT). However, COVID-19, geopolitical eruptions, and the rise of extreme weather events have turned JIT’s benefits into liabilities,” says Fortune magazine. “In 2021 alone, the cost of U.S. business logistics rose 22%.”

In line with the strategy’s name, companies opting for the JIT method rely heavily on orders being fulfilled right on time. Still, this approach is becoming increasingly unfeasible, considering the supply chain and shipping disruptions plaguing today’s market.

Let’s zoom in a little further on the pros and cons of the JIT inventory approach.

Pros & Cons of JIT

Here are just a few advantages and drawbacks of the just-in-time inventory restocking method:

| Pros of JIT inventory | Cons of JIT inventory |

| You’re mitigating the risk of buying and storing materials that ultimately don’t sell. | You’re at the mercy of unreliable supply chains to get your inventory on time. |

| You’re saving money by decreasing the need for storage space and minimizing logistical reshuffles of stock. | You’re risking the genuine potential of significant shipping delays. |

| You’re not stuck with mass inventory of a deprecated product when demand shifts to newer products. | You’re unprepared for unpredictable spikes in demand. |

In an ideal market, JIT inventory can reduce costs and promote efficiency. However, some are beginning to turn from this idealistic approach in today’s chaotic and ever-disrupted market. Instead, they’re implementing new supply chain optimization strategies and striving to account for uncontrollable factors, like shipping and unpredictable demand.

The dawn of a new supply chain world has made demand patterns more unpredictable and will likely remain so for the foreseeable future. Companies have started adapting the new supply chain mindset – from Just-in-Time to Just-in case, and are redefining their supply chain strategies to manage demand shifts and build forward-looking processes to identify any potential supply disruptions.

As mind-bending as it sounds, the question is; How can global traders optimize their supply chain optimization strategy?

How to Avoid the Risks of Supply Chain Over-Optimization

Today’s global traders – whether operating on an enterprise level or just getting started – are looking for ways to optimize their processes. However, the JIT example above illustrates the risks of over-optimization. What are some actionable methods for minimizing liability while promoting efficiency?

Here are several noteworthy ways to mitigate supply chain optimization risks backed by strong voices in the world of finance:

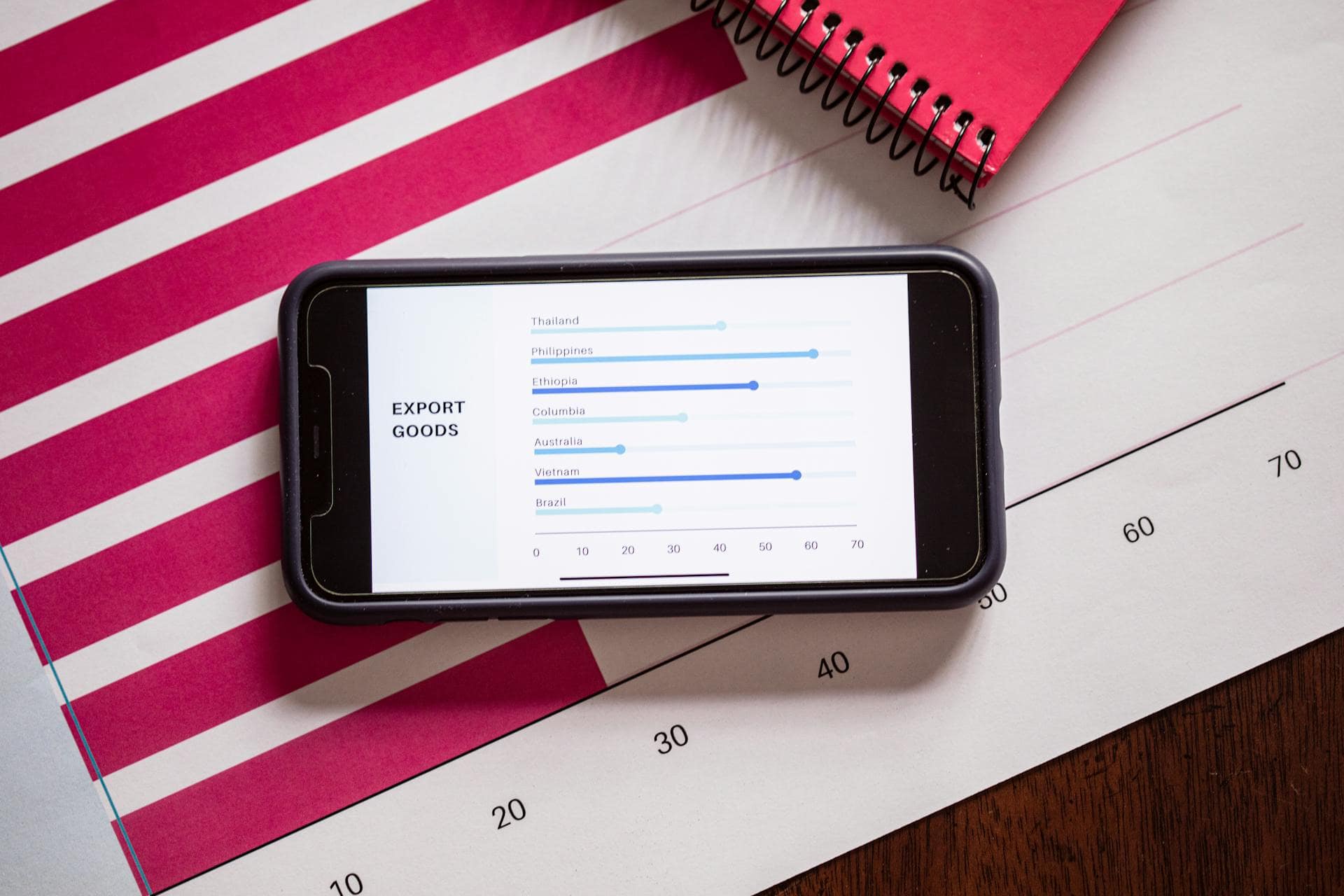

- Pay attention to the market and invest in analytics. – “More-accurate order forecasts clearly translate into a more effective supply plan, which reduces lost sales,” explains Harvard Business Review.

- Leave a margin for error. – “Instead of solely focusing on reestablishing yesterday’s equilibrium, buyers would do well to enact structural changes to the way they procure or even manufacture their own products to minimize exposure to these new risks. This entails a shift to ‘just-in-case’ inventory (JIC),” says Fortune. “However, embracing JIC supply chain strategies does not mean ignoring the benefits of JIT, nor does it entail a return to the past. Effective backups in a post-COVID age mean more tech integration, more data tracking, and more communication than ever before.”

- Balance technology with a human touch. – “The human dimension is back, and it will play a prime role in rebalancing the global supply chain during this crisis, and well beyond,” states a professor from the International Institute for Management Development. “Big and unexpected changes in volume render statistical models useless. These assess events such as the pandemic as “outliers” and, therefore, discard them from the data. Although we need visibility for the people in the supply chain to be able to make decisions, most decisions should be made manually. Ergo, the human factor is key.”

- Find the right supply chain management tools. -“A company must invest in responsible supply chain management to react to disruptions effectively and sustainably to survive the competitive climate and guarantee qualitative development,” advises Let’s Talk Finance. “When a company uses efficient supply chain management, it gains a competitive edge in its sector by lowering the inherent risks associated with purchasing raw materials and selling products or services.”

Leveraging technology enables implementing highly effective supply chain processes within an organization, performing due diligence and eliminating information silos with improved data transparency and collaboration, thereby ensuring end-to-end sustainability across the supply chain.

Yes, combining the right analytics and tools with the human factor and room for error can help global traders optimize their supply chain without over-optimizing.

Which supply chain optimization tools can help your company boost profitability?

Supply Chain Optimization Tools for Increased Efficiency and Less Liability

Creating resilient supply chains is admittedly more challenging than ever. That’s why global traders need better and more dynamic supply chain optimization tools than ever.

At OCR Global Trade Management, we provide powerful software solutions for global supply chain management without losing the human touch. Our web-based tools integrate with your existing IT landscape, promoting efficiency while minimizing liability. From automating Import Operations and Broker Management to Export Controls and Order Management, we can help you become more agile and profitable.

Get in touch today to join our roster of successful global companies that partner with us.