Post-Pandemic Global Supply Chain Complexity and Disruption

At the outset of the pandemic, consumers’ buying habits changed. Since people were spending more time at home and facing a public health crisis, they needed more at-home supplies and personal hygiene products.

Most of us remember the sudden demand for items like toilet paper, masks, and hand sanitizer – along with the subsequently empty shelves. Unfortunately, pre-pandemic supply chains simply could not keep up with these new and unexpected demands.

Many businesses are working hard to get back on their feet in a post-pandemic market. Additionally, more and more consumers are returning to in-person shopping. However, despite the demand, companies everywhere are losing potential revenue due to the lack of supplies.

Some businesses “do not have enough of their products in inventory to avoid running out of stock,” observes The White House. “The situation has been especially difficult for businesses with complex supply chains, as their production is vulnerable to disruption due to shortages of inputs from other businesses.”

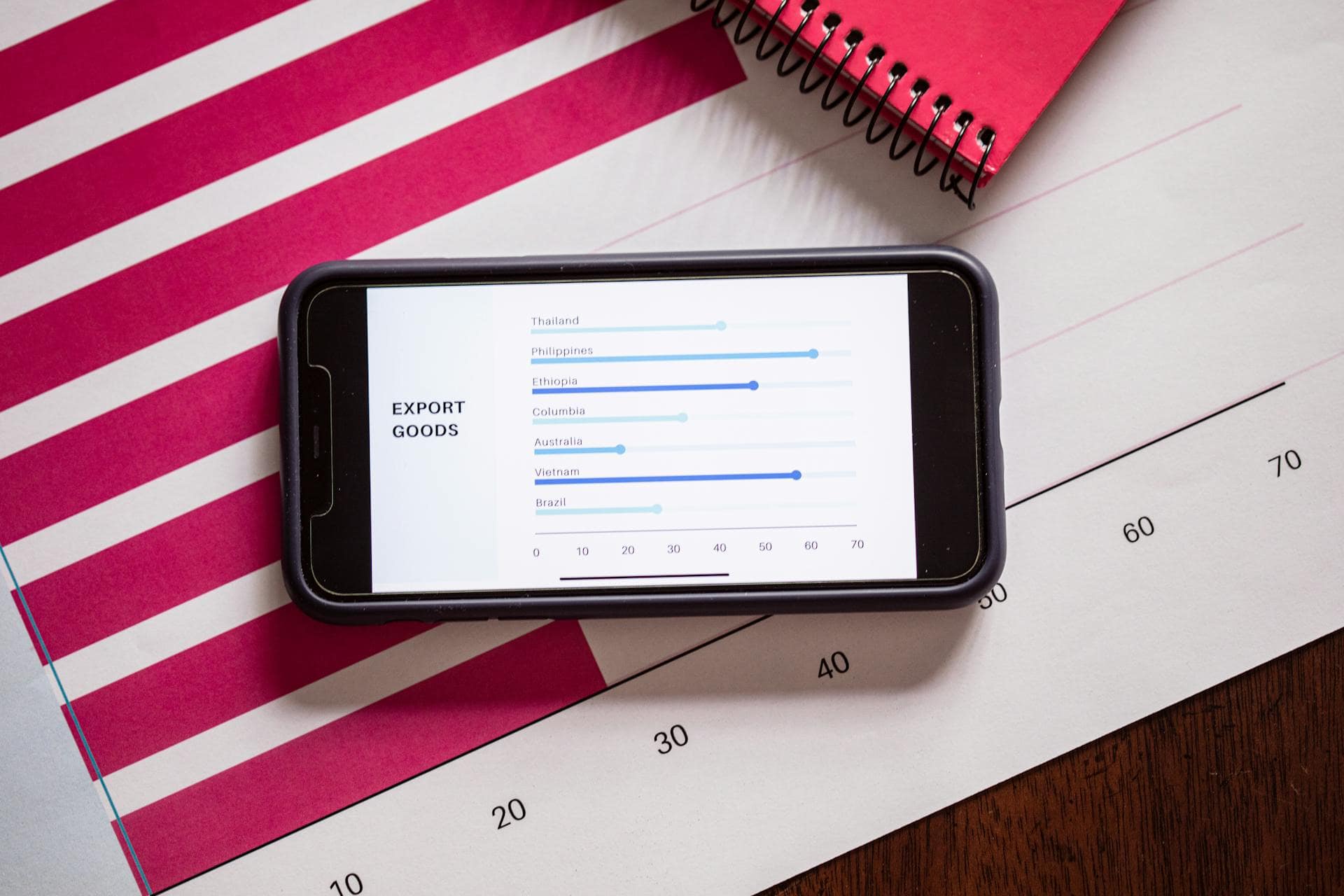

Yes, many industries, like the technology and automotive industries, which rely heavily on imported materials and components, have found it incredibly tricky to keep enough inventory to satisfy the current demand.

What other factors are contributing to the disruption of the global supply chain?

Contributing Factors to Global Supply Chain Disruption

Beyond the global pandemic, tensions between giants in the international trade landscape also contribute to global supply chain issues.

“The U.S.-China trade war and the supply and demand shocks brought on by the Covid-19 crisis are forcing manufacturers everywhere to reassess their supply chains,” says Harvard Business Review. “For the foreseeable future, they will face pressure to increase domestic production, grow employment in their home countries, reduce their dependence on risky sources, and rethink strategies of lean inventories and just-in-time replenishment, which can be crippling when material shortages arise.”

These geopolitical factors continually impact global trade, making traders reassess their strategies and supply chains.

Tips for Mitigating Global Supply Chain Risks

What can global traders do to minimize financial risk in an ever-dynamic market? Many companies have successfully navigated the uncertain post-pandemic global trade landscape.

To mitigate global supply chain risks, companies can start by:

Minimizing the number of suppliers. – If possible, it may help to pair down the number of suppliers you use. Otherwise, you risk letting materials from Supplier A go to waste while waiting on other materials from Supplier B that never arrive. It may be best to find a supplier that can provide several of the materials or components you need so that your supply chain is not overly complicated or dependent on too many variables. Of course, by minimizing your number of suppliers, you risk ‘putting all your eggs in one basket,’ so to speak. For this reason, some traders may prefer to have multiple suppliers for the same material. That way, if Supplier A can’t deliver or goes out of business, you already have a relationship with Supplier B, and they may be able to come through.

Screening suppliers carefully. – Choose your suppliers carefully. Do your due diligence with denied party screening to ensure you avoid unreputable or illegal suppliers. Take time to research each supplier. Learn about their reputation and what they are doing to address supply chain issues.

Balancing optimization with slack. – While finding ways to automate operations and boost efficiency is key, leaving a little slack in your supply chain plan for the unknown is also essential. With the global supply chain in disarray, there are uncontrollable factors for which to account. So give yourself a generous bumper when it comes to ordering, and expect longer shipping times and other logistical hiccups. Hope for the best, but plan for the worst.

Expanding storage options. – Some companies are getting away from ‘just-in-time’ restocking and finding logistical solutions to having more inventory on hand. Of course, more inventory means more overhead and comes with the risk that the product may not sell. Still, if there is a product or material that you are consistently running low on, find a way to build your stock if possible, legal, and safe.

Finding trusted shipping and logistics partners. – The pandemic has disrupted nearly all couriers and logistics companies, and shipping times have multiplied. Still, strive to find the best shipping companies you can. Then, avoid stress by ordering early, when prudent.

Investing in supply chain management tools. – Find global supply chain management tools to help you automate processes to save time, manage logistics, and de-stress customs paperwork.

Implementing the above strategies may help your company stay resilient and profitable. Still, since no two globalized companies are the same, each must examine its unique circumstances and needs when creating the best supply chain strategy.

In doing so, what tools can help you get ahead of global supply chain management?

Tools for Global Supply Chain Management

Money is tight coming out of the pandemic and facing a recession. However, investing in the right global trade management tools can help mitigate risk and promote profitability.

OCR Global Trade Management offers a user-friendly, web-based platform flush with tools to help you manage your global supply chain and logistics. From denied party screening to carrier integration, our powerful software can do the heavy lifting for you.

Get in touch with our sales team to get started.